The company

Production tour

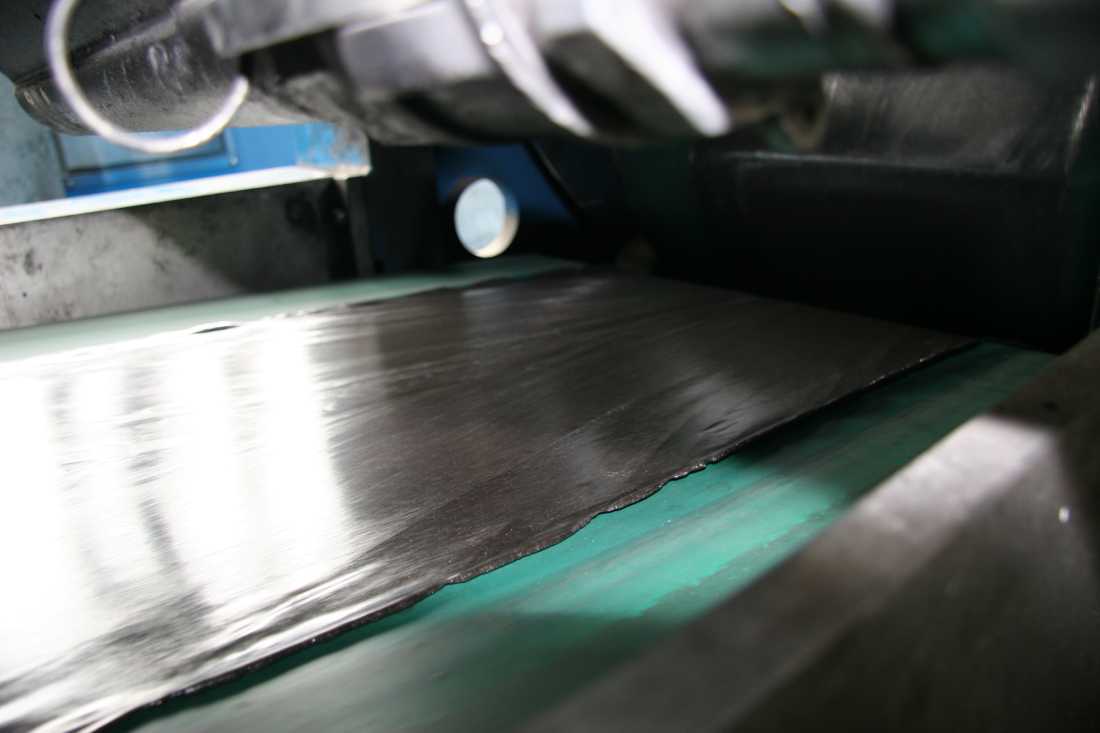

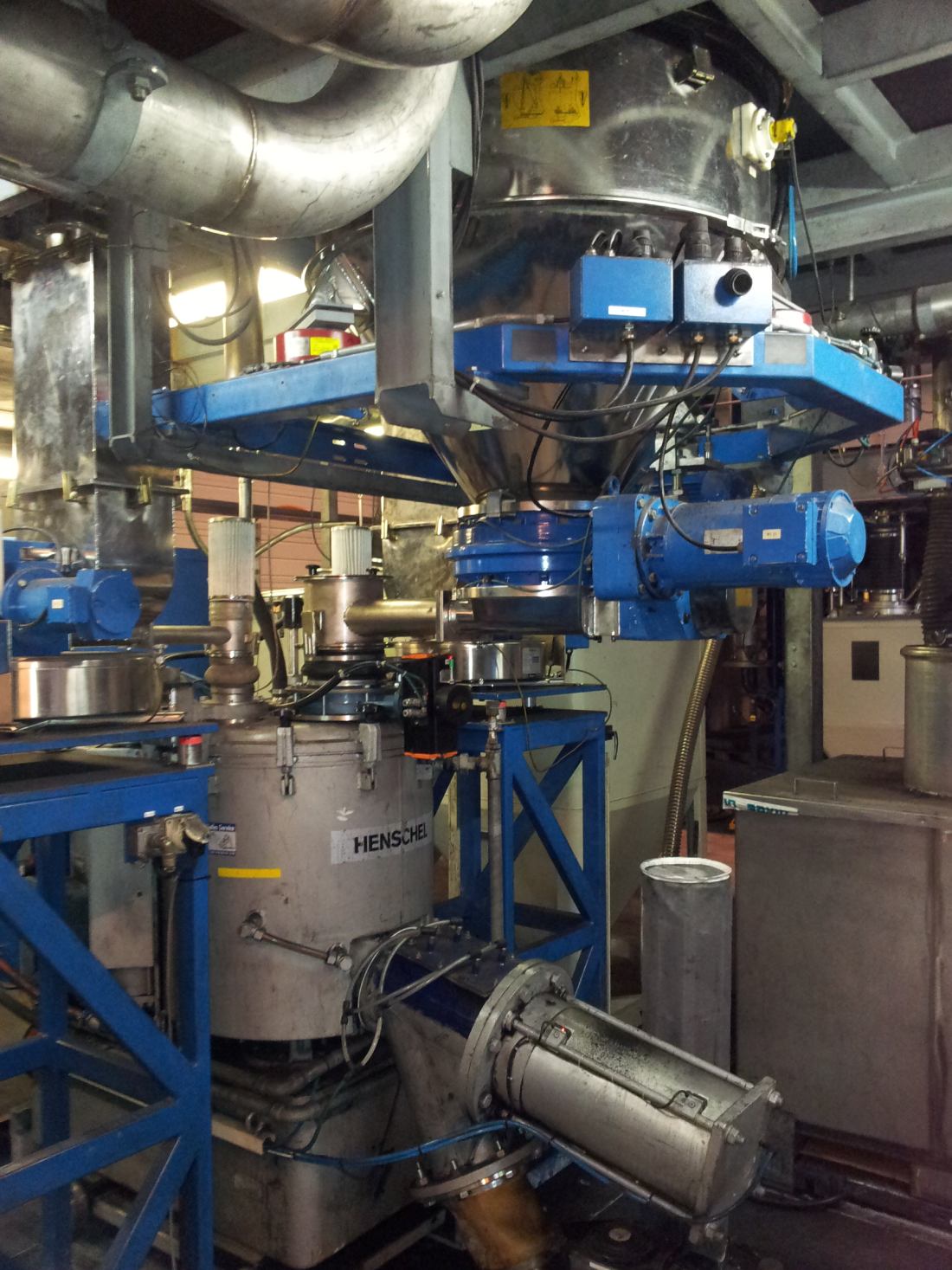

INTEGRAL processes only the best special raw materials for the production of monochrome and color toners. As the first stage of production, the raw materials are fed into the production process from storage containers. The even distribution of the raw materials takes place during the premixing process using a high-speed mixing process. Highly specialized extrusion lines ensure perfect compounding of the toner raw materials. The extruded raw materials are then pulverized using the air jet grinding process. Particles that are too coarse or too fine are removed from the production process by means of a sifting process. The raw toner produced is then provided with the required special surface additives by means of a coating process. A final safety sieving process ensures that the toner is free of agglomerates and can be used for further cartridge production.

The results can be seen in the form of stable image quality, high copy and printer yields and particularly low service costs for the copy and print systems in which INTEGRAL toner is used.